|

The Control Web system is a software framework that can perform in

a wide variety of roles. It can be used in machine controllers, can

integrate manufacturing technologies with enterprise information

systems or be used as a data server with many web clients. It can

model and simulate processes, create complex and demanding

visualizations and much more. In other words, it can be used in

virtually any way you would need.

For some, the Control Web system can be an affordable tool

which enables them to inexpensively set-up and manage a small

hydropower plant. For others, it can be a instrument for creating a

large distributed enterprise application with tens of thousands of

measure points, containing hundreds of operator displays working on a

number of networked computers. For students, it can be a tool which

saves them a lot of work during laboratory and other exercises by

modeling, simulating and visualizing tasks, as well as automatically

measuring and printing logs. The unified environment provide

application developers with components and services including a

graphical development environment to quickly address all the demands

of today's modern automation systems.

Simple and intuitive development environment

|

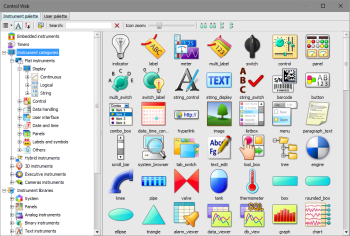

In the Control Web system, the application

is built up from components called virtual

instruments. For instance, the meter

instrument is used for displaying an analog value, whereas

the more complex alarm_viewer instrument can

be used for working with alarms and alarm lists. The

behavior of virtual instruments is affected by

user-adjustable parameters. Furthermore, it is possible to

create even more complicated application behavior by writing

own scripts. For a detailed description of the

development environment, see this article. A sample of the first

application in Control Web can be found here. |

Possibility to connect any hardware (OPC, OPC UA, Modbus,

Simatic, etc.)

|

In Control Web, the so-called drivers are used to

connect to and communicate with peripheral devices. Some

drivers are a part of the system installation. Some need to

be installed separately. Drivers included:

Serial communication (COM, etc.) Microsoft Excel integration Drivers for simulation and application tests

Additional drivers available:

DataLab IO OPC client and OPC UA client Modbus serial and Modbus TCP Simatic TCP, Simatic prodave, Simatic PPI, etc.

HTTP client PLC Tecomat, Saia, Allen-Bradley, etc. A complete list of drivers, including their

documentation, can be found here.

|

Beautiful applications thanks to the support of modern

rendering technologies

|

Control Web allows you to draw static and

dynamic images quickly and efficiently in the integrated

graphics editor of the development environment.

Ability to dynamically adjust applications by

the monitor resolution of the target computer. The graphics and image program components in the

Control Web system make use of the parallel

performance of modern graphics processors. |

VisionLab - machine vision software for the Control Web

system

|

The Vision Lab system for creating machine

vision applications cannot work alone, but only as a

component of a more universal system for industrial

real-time applications - the Control Web system.

Integrating the Vision Lab system into the

Control Web system - a widely used system for

developing technological processes visualisation

applications, real-time control application, etc. - brings

many advantages. Owing to the full integration into

the Control Web system, machine vision applications

of the Vision Lab system can benefit from all

advantages and features of the Control Web system.

A machine vision development system lacking these features

would be very constraining and majority of the users would

struggle to solve the data exchange between visualization

applications, processes control applications and the

application for machine vision itself. This would naturally

make costs higher and development process longer and more

difficult. |

|